|

|

|

|

|

BRASS ALLOYS

BRONZE ALLOYS

COPPER ALLOYS

Machined Components

| |

|

| Chemical Requirements | CuZn42Pb2 | CuZn40Pb2 |

| Copper | 56.5 - 60.0% | 57.0 - 59.0% |

| Lead | 0.60 to 2.0% | 1.5 to 2.5% |

| Iron | 0.30% max | 0.40% max |

| Total Imp. Excl. Iron | 0.20% max | 0.70% max |

| Zinc | Remainder | Remainder |

| Physical Properties | ||

| Tensile Strength | 380 Mpa Min | 40 kg/mm2 Min. |

| Elongation % | 25% Min | 18% Min. |

| Izod Value | - | 2.0 KJ min |

| Fabrication Properties | ||

| Capacity for being | ||

| Cold worked | Poor | Poor |

| Hot formed | Excellent | Excellent |

| Hot forgeability rating | 100% | 100% |

| Machinability Rating | 80% | 80% |

| Suitability for soldering | Excellent | Excellent |

| Suitability for Brazing | Good | Good |

| Uses | ||

| Forged Components, Industrial Valves, Defense components, Watch Case, Automobile Valves Components | ||

| Chemical Requirements | HT1 | HT2 | |||

| Copper | 56.0 - 60.0% | 56.0 - 61.0% | |||

| Lead | 0.20 to 1.50% | 0.50 to 1.50% | |||

| Iron | 0.20 to 1.25% | 0.20 to 1.50% | |||

| Tin | 0.20 to 1.0% | 1.0% max | |||

| Aluminum | 0.2% max | 0.30 to 2% | |||

| Manganese | 0.25 - 2.0% | 0.50-2.0% | |||

| Total Imp. | 0.50% max | 0.50% max | |||

| Zinc | Remainder | Remainder | |||

| Physical Properties | |||||

| Condition | Size | T.S. MPa | EL% Min | T.S. MPa | EL% Min |

| As manufactured | All Size | 430 min | 20% | 460 min | 20% |

| Cold-worked & Stress | 10-40 | 480 min | 12% | 520 min | 12% |

| Relieved | 40 above | 500 min | 15% | ||

| Fabrication Properties | |||||

| Capacity for being | |||||

| Cold formed | Poor | Fair | |||

| Hot worked | Good | Good | |||

| Machinability Rating | 30% | 30% | |||

| Resistance to Corrosion | Excellent | Excellent | |||

| Suitability for soldering | Excellent | Fair | |||

| Uses | |||||

| HT1 is suitable for Soldering | |||||

| Ht2 is suitable for Machining | |||||

| Chemical Requirements | CuZn35Pb1 | CuZn35 | ||

| Copper | 62.0 - 65.0% | 63.0 - 68.0% | ||

| Lead | 0.75 to 1.50% | 0.02% max. | ||

| Iron | 0.10% max | 0.05% max | ||

| Total Imp. | 0.50% max | 0.30% max | ||

| Zinc | Remainder | Remainder | ||

| Physical Properties | ||||

| Condition | T.S. MPa | EL% Min | T.S. MPa | EL% Min |

| Quarter Hard (HA) | 325-390 | 30% | 340-345 | 30% |

| Half-Hard (HB) | 400-490 | 20% | 420-510 | 15% |

| Hard (HD) | 500-685 | 15% | - | - |

| Extra Hard (HE) | 695-885 | 5% | - | - |

| Fabrication Properties | |

| Capacity for being | |

| Cold forming | Excellent |

| Machinability Rating | 70% |

| Bending | Excellent |

| Riveting | Excellent |

| Uses |

| Ductile Alloy with good combination of bending as well as cold heading properties |

| Chemical Requirements | Grade I | ||

| Copper | 56.0 - 59.0% | ||

| Lead | 2.0 to 3.50% | ||

| Iron | 0.35% max. | ||

| Total Imp. Excl. Iron | 0.70% max. | ||

| Zinc | Remainder | ||

| Physical Properties | |||

| Condition | Size | T.S. MPA | EL% Min |

| Annealed (O) | 6-25 25-50 50 above |

345 315 285 |

12 17 22 |

| Half-Hard (HB) | 6-12 12-25 25-50 50 above |

405 395 355 325 |

4 6 12 17 |

| Hard (HD) | 6-12 12-25 |

550 490 |

- 4 |

| Fabrication Properties | |||

| Capacity for being | |||

| Cold worked | Poor | ||

| Hot formed | Fair | ||

| Machinability Rating | 100% | ||

| Suitability for soldering | Excellent | ||

| Suitability for Brazing | Good | ||

| Uses | |||

| Precision Components, Hardware, Hinges, Lock Bodies, Screws, Nuts & Bolts | |||

| Chemical Requirements | Grade II | Grade III | |||

| Copper | 60.0 - 63.0% | 60.0 - 63.0% | |||

| Lead | 2.50 to 3.70% | 0.50 to 1.50% | |||

| Iron | 0.35% max | 0.20% max | |||

| Total Imp. Excl. Iron | 0.50% max | 0.50% max | |||

| Zinc | Remainder | Remainder | |||

| Physical Properties | |||||

| Condition | Size | T.S. T.S. MPA | EL% Min | T.S. MPA | EL% Min |

| Annealed (O) | 6-25 25-50 50 above |

355 305 275 |

15 20 25 |

315 285 255 |

22 27 32 |

| Half-Hard (HB) | 6-12 12-25 25-50 50 above |

395 385 345 315 |

7 10 15 20 |

355n 345 305 285 |

8 12 22 27 |

| Hard (HD) | 6-12 12-25 |

550 485 |

4 |

460 400 |

4 |

| Fabrication Properties | |||||

| Capacity for being | |||||

| Cold worked | Poor | Fair | |||

| Hot formed | Fair | Excellent | |||

| Machinability Rating | 90% | 80% | |||

| Suitability for soldering | Excellent | Excellent | |||

| Suitability for Brazing | Good | Excellent | |||

| Uses | |||||

| Gr II : Gear, Pinions, Precision, Automobile, Electronic Parts | |||||

| Gr III : Precision Components Machining with Riveting Operation | |||||

|

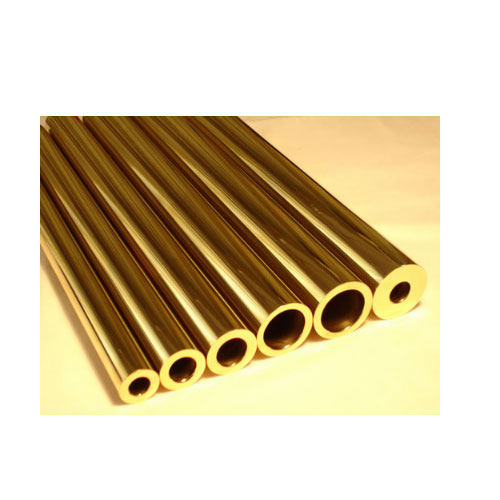

| Rod Brass |

|

| Naval Brass |

|

|

|

|

|

Naval Brass Rod |

Naval Brass Application |

| Chemical Requirements | Garde I | Grade II | |||

| Copper | 61.0 - 64.0% | 59.0 - 62.0% | |||

| Lead | 0.20% max | 0.50 to 1.0% | |||

| Tin | 1.0 to 1.50% | 0.50 to 1.0% | |||

| Iron | 0.10% max | - | |||

| Other Imp. | 0.20% max | 0.20% max | |||

| Zinc | Remainder | Remainder | |||

| Physical Properties | |||||

| Condition | Size | T.S. 2 Kg/mm2 | EL% Min | T.S. 2 Kg/mm2 | EL% Min |

| Half-Hard (HB) | Upto 12.5 12.5 to 50 50 to 100 |

40 min 38.5 min 35 min |

18% 18% 18% |

40 min 40 min 40 min |

15% 15% 15% |

| Fabrication Properties | |||||

| Capacity for being | |||||

| Cold Worked | Fair | Poor | |||

| Hot Worked | Excellent | Good | |||

| Machinability Rating | 30% | 50% | |||

| Forgeability Rating | 90% | 90% | |||

| Silver Alloy Brazing | Excellent | Excellent | |||

| Soft Soldering | Excellent | Excellent | |||

| Oxyacetylene Welding | Good | Not Suitable | |||

| Uses | |||||

| Gr I : Condenser Components, Propeller Shaft, Marine hardware where bending is required. | |||||

| Gr II : Marine Hardware, Screw Machine, Valve Stems and Components for Naval use. | |||||

|

| Chemical Requirements | |||||

| Copper | Lead | Iron | Total Imp. | Zinc | |

| Free Cutting Brass Hollow Rods BS 2874/86- Cz121 Pb3 / CZ124 | |||||

| Grade I | 56.0 - 59.0% | 2.0 - 3.50% | 0.35% max | 0.70% max | Remainder |

| GradeII | 60.0 - 63.0% | 2.50 - 3.70% | 0.35% max | 0.50% max | Remainder |

| GradeIII | 60.0 - 63.0% | 0.50 - 1.50% | 0.20% max | 0.50% max | Remainder |

| Forging Brass Hollow Rods CZ 122 / IS 8737 | |||||

| CuZn42Pb2 | 56.5 - 60.0% | 0.60 - 2.0% | 0.30% max | 0.20% max | Remainder |

| CuZn40Pb2 | 57.0 - 59.0% | 1.50 - 2.50% | 0.40%max | 0.70%max | Remainder |

| Lead Free Brass Hollow Rods BS2874/86 , IS 4170/67, CZ109 BS2872/86 / IS 4413/81, CZ108 | |||||

| CuZn40 | 59.0 - 62.0% | 0.75% max | 0.10% max | 0.30% max | Remainder |

| CuZn37 | 62.0 - 65.0% | 0.30% max | 0.10% max | 0.60% max | Remainder |

| CuZn35 | 63.0 - 68.5% | 0.05% max | 0.05% max | 0.30% max | Remainder |

| CuZn30 | 68.5 - 71.5% | 0.05% max | 0.05% max | 0.03% max | Remainder |

|

| Chemical Requirements | CuZn40 | CuZn35 | CuZn37 | CuZn30 |

| Copper | 59.0 - 62.0% | 63.0 - 68.5% | 62.0 - 65.0% | 60.5 - 71.50% |

| Lead | 0.75% max | 0.05% max | 0.30% max. | 0.05% max. |

| Iron | 0.10% max | 0.05% max | 0.10% max | 0.05% max |

| Total Imp. | 0.30% max | 0.30% max | 0.60% max | 0.30% max |

| Zinc | Remainder | Remainder | Remainder | Remainder |

| Minimum Order Quantity | 250 Kg |

| Glass Thickness | A per Drawing |

| Minimum Order Quantity | 250 Kg |

| Glass Thickness | 4 mm Min and As per customer Drawing |

Developed and Managed by IndiaMART InterMESH Limited |